Part number: 8200Manufacturer SKU:

For current pricing and to place an order please contact your Ellsworth Customer Service Representative.

Call Us Contact Customer Service at +852 - 28058333。

Live Chat Speak with one of our Technical Service Personnel.

Request a Quote Submit a quote request and a Sales Representative will contact you.

Send an Email We will respond within 1 business day.

-

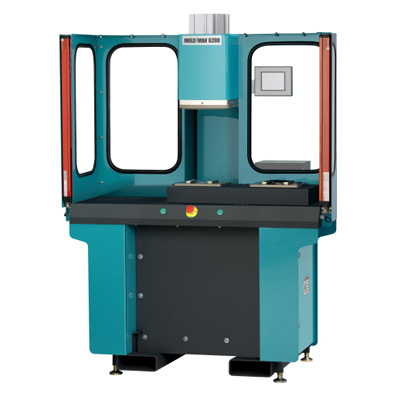

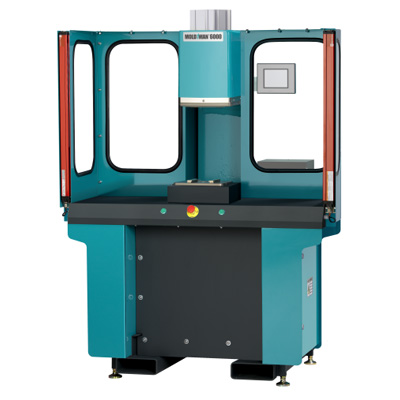

DescriptionThe Mold Man® 8200 Thermoplastic Machine is a high-volume model designed for dispensing thermoplastic materials such as copolyesters and polyamides. Includes touch screen controls, 5.5 ton clamping force, exact pressure control, and requires integration with up to two Melt Man™ material melt units. The Mold Man® 8200 is CE compliant.

-

Product Details

MODELS

Mold Man® 8200TP FEATURES

Run one or two melt/processing units at the same time Run different molding materials or parameters at the same time Two melt units can pump up to 40 grams/sec Designed for high volume production runs above 250,000 units per year Shuttle table operation, practically double your output User-friendly operation Mold up to eight cavities at the same time (depending on part size) Fully independent adjustable process control (closed loop processing) Precisely meter shot sizes, accurate control flow rates, and exact pressure control Patented permanent nozzle engagement for fewer moving parts SPECIFICATIONS

Height 1950 mm / 77” Width 1925 mm / 76” Depth 1150 mm / 45.5” Weight 795 kg / 1750 lbs Min. Footprint 1925 mm X 1676 mm / 76” X 66” (includes 8200 and melt units) Power Supply 200-240 VAC

Single Phase: 50/60 Hz, 30 AAir Pressure Min. 6 bar / 90 psi Air Volume Min. 120 lpm / 4 SCFM Clamp Servo electric driven ballscrew with pneumatic booster Clamping Force 49 kn / 5.5 tons Clamp Stroke 203 mm / 8” Ejector Pneumatic Ejector Force 180 kg / 400 lbs Ejector Stroke 20 mm / 0.79” Shuttle Table Servo electric driven ballscrew Shuttle Table Stroke 525 mm / 20.67” Maximum Mold-set Footprint 300 mm X 250 mm / 12” x 10” Injection Nozzle Patented permanent engagement in upper mold-half Operator Interface 190 mm / 7.5” color touch screen for easy access to molding parameters

Includes customizable alarm screens, cycle counter, auto-start timer, etc.Safety Features Safety light curtain, see-thru clamp shield, soft close feature/foreign object

Sensing in clamping cycle, password protection for setup screens

Emergency stop palm buttonACCESSORIES

Melt Man™ Material Melt Unit For doubled melt capacity or as backup unit for different materials/colors Double Clamping Cylinder Mold-set Cooling Kit Includes chiller, hoses and fittings -

Ellsworth Adhesives Insights

-

SDS / TDS